Original

Equipment Manufacturer

Rubber Injection Molding Parts

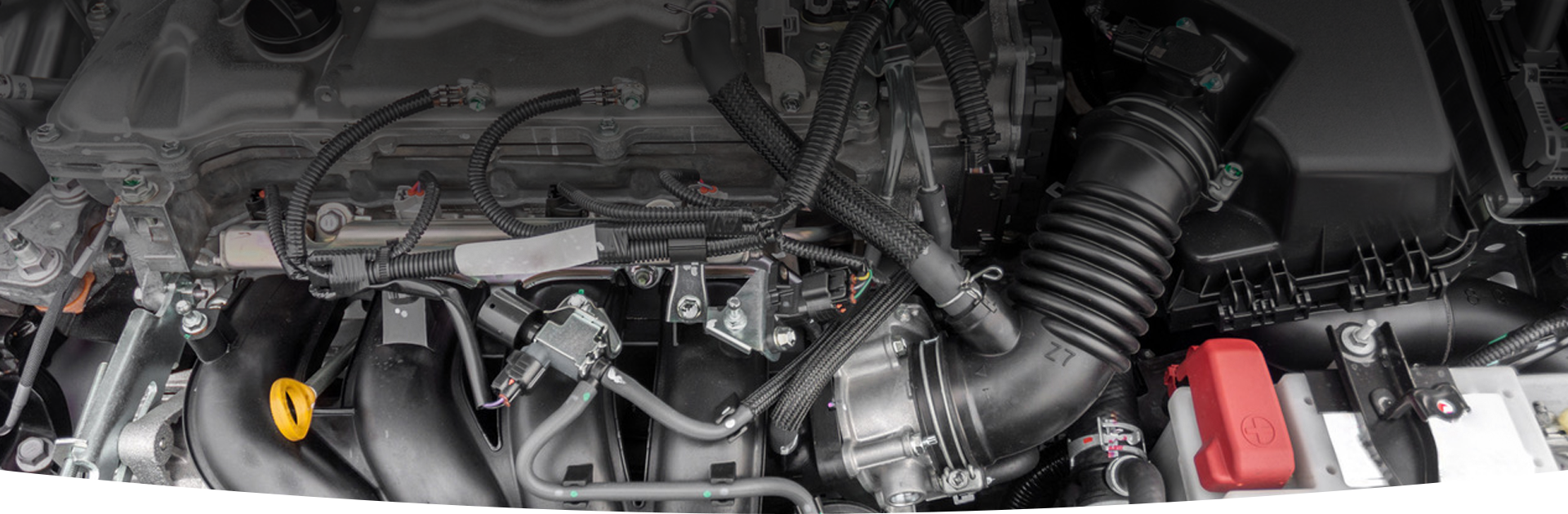

In rubber injection molding, an uncured rubber ribbon stock is fed into a rotating screw of the injection unit where the material is plasticized to a target elevated temperature. At wipe rubber division, high-precision, advanced anti-vibration rubber products are manufactured on state of the art Desma injection molding machines. Wipe rubber division has 19 Desma machines ranging from 160T to 250T to manufacture a wide variety of air cleaner hoses, shocker caps, seat springs, engine mountings, buffers, bushes and a variety of rubber mountings. Hoses come in many different types with a diversified range of specifications and the procedures/techniques used for production vary greatly. Production is carried out efficiently by selecting the most suitable manufacturing method. The most important product of our line-up is the air cleaner hose that direct clean air from the air cleaner to the engine.

A state of the art rubber kneading lines are installed at our Lucknow plant. The line is manually controlled for all aspects of the process, from measuring the quantity of raw ingredients through to kneading the rubber in mixers and drawing it out, ensures the production of rubber with stable and consistent levels of quality. Wipe is considering to install a computer controlled line by 2020.

High-precision rubber injection moulding products are produced on the many adaptable compact DESMA injection molding machines. Through the application of heat and chemical reaction in the injection molding machines it serves to complete the advanced anti-vibration rubber products.

Wipe has set up a special tool room in our Jagdishpur and Lucknow plant for manufacturing molds driven by high level of know-how and state of the art facilities. For advance high-function performance auto components, greater accuracy, precision and speed are required for producing the molds vital for molded products and as for the molds required to build wiper arm and blade child parts.